What is Plan-Do-Check-Act (PDCA) Cycle?

- Editorial Team

- Published 21-Oct-2025

- What is the PDCA Cycle?

- How the PDCA Model Works in Practice

- When to Use the PDCA Cycle

- Understanding Each PDCA Step

- Why the PDCA Cycle Still Works Today

- Real-World Examples of PDCA in Action

- Common PDCA Mistakes (and How to Avoid Them)

- Advantages of the PDCA Cycle

- When PDCA May Need Adaptation

- PDCA in Everyday Life

- Conclusion

- FAQs on PDCA Cycle

The Plan-Do-Check-Act (PDCA) Cycle, also known as the Deming Cycle, is one of the most time-tested models for continuous improvement in organizations. Originally developed by Walter Shewhart in the 1920s and later refined by W. Edwards Deming, it provides a structured, repeatable method for turning ideas into measurable progress.

Today, PDCA drives success across sectors, from manufacturing and healthcare to education and public administration. Its enduring strength lies in its simplicity, adaptability, and focus on learning by doing.

Become future-ready with our Business Programs

Know MoreWhat is the PDCA Cycle?

The PDCA Cycle is a four-step, iterative process used to improve processes and products by applying systematic experimentation and analysis.

| Phase | Purpose | Key Actions |

| Plan | Identify opportunities and set objectives | Analyze current situation, define goals, develop solutions |

| Do | Implement the plan on a small scale | Test ideas, train staff, document outcomes |

| Check | Evaluate results against objectives | Measure performance, identify deviations |

| Act | Standardize success or restart the cycle | Apply improvements or adjust based on findings |

Unlike one-time initiatives, PDCA operates as a continuous loop, each cycle feeding into the next, ensuring constant refinement and innovation.

How the PDCA Model Works in Practice

In practice, the PDCA cycle helps teams test ideas systematically rather than relying on intuition.

- Plan: Teams analyze performance data, identify areas for improvement, and create a roadmap.

- Do: Changes are implemented on a pilot scale to minimize risk.

- Check: Data is collected and compared with expected outcomes.

- Act: If successful, changes are standardized; if not, teams return to planning with new insights.

Example:

A hospital introducing a new patient handover system tests it first in one department (Do), monitors error rates (Check), and then rolls it out hospital-wide (Act) after refining the process.

When to Use the PDCA Cycle

The PDCA model can be applied to nearly any improvement initiative, but it’s most effective when:

- A process needs consistent optimization or waste reduction.

- A new policy or system is being introduced.

- There’s a need to analyze failures and identify root causes.

- Teams want to experiment safely before full implementation.

- Projects require evidence-based evaluation rather than assumptions.

Best-fit scenarios:

- Manufacturing quality control

- Service delivery improvements

- Academic program design

- Healthcare process optimization

- Employee training or onboarding enhancements

Linking PDCA to Organizational Progress

Each PDCA phase contributes uniquely to sustained progress:

- Plan: Sets measurable objectives and baselines.

- Do: Converts ideas into action, creating engagement.

- Check: Validates what worked and what didn’t.

- Act: Institutionalizes success for long-term results.

This systematic flow ensures steady, data-driven progress rather than sporadic, unsustained initiatives.

Understanding Each PDCA Step

Composed of four steps: Plan, Do, Check, and Act, it is important to be aware of PDCA cycle at each step and what it entails.

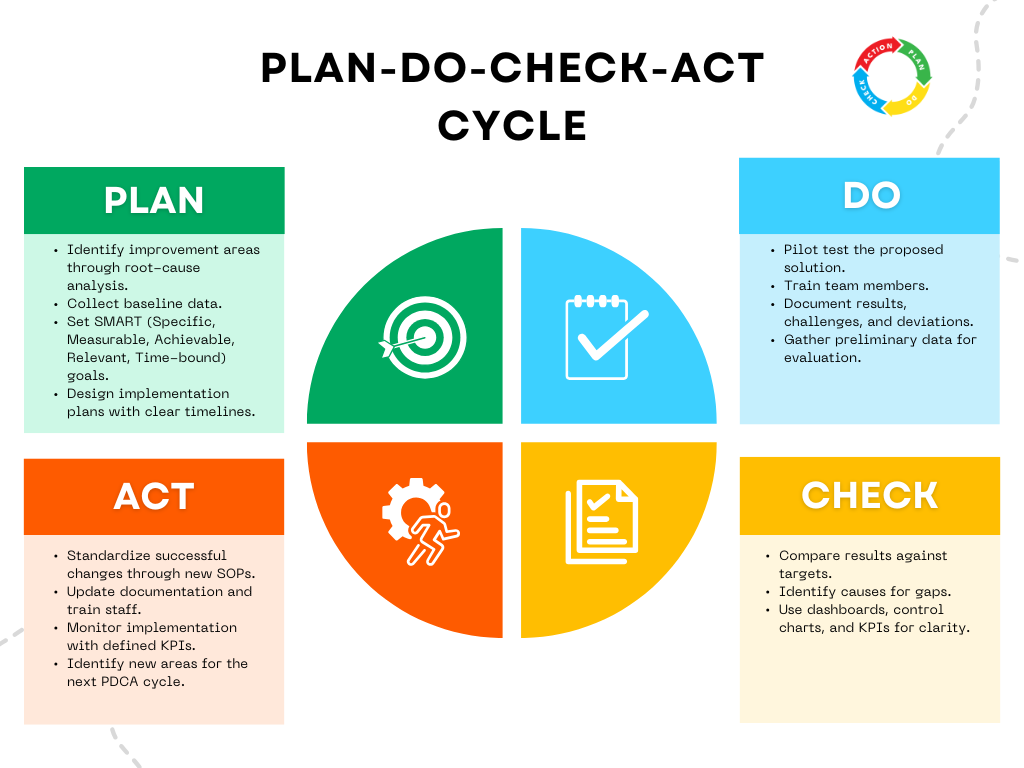

1. Plan: Laying the Foundation

The Plan phase is the analytical backbone of PDCA.

Key actions:

- Identify improvement areas through root-cause analysis.

- Collect baseline data.

- Set SMART (Specific, Measurable, Achievable, Relevant, Time-bound) goals.

- Design implementation plans with clear timelines.

Tip: Use tools like Fishbone Diagrams, Pareto Charts, and 5-Why Analysis to define the problem accurately.

2. Do: Implementing the Plan

The Do phase puts the plan into action but on a small, controlled scale.

Key actions:

- Pilot test the proposed solution.

- Train team members.

- Document results, challenges, and deviations.

- Gather preliminary data for evaluation.

Example: A school testing a new teaching method in one class before full rollout.

3. Check: Reviewing the Results

Often the most neglected phase, Check ensures decisions are based on data, not assumptions.

Why it’s skipped:

- Pressure to move fast.

- Lack of data systems or analytical skills.

- Cultural bias toward “action over reflection.”

How to do it right:

- Compare results against targets.

- Identify causes for gaps.

- Use dashboards, control charts, and KPIs for clarity.

Remember: Skipping this step turns PDCA into “Plan-Do-Act,” removing the evidence-based rigor essential for progress.

4. Act: Standardizing and Scaling Up

The Act phase closes the loop and sustains improvement.

Key actions:

- Standardize successful changes through new SOPs.

- Update documentation and train staff.

- Monitor implementation with defined KPIs.

- Identify new areas for the next PDCA cycle.

This phase ensures continuous learning and organizational memory, preventing regression into old habits.

Why the PDCA Cycle Still Works Today

Despite its origin nearly a century ago, PDCA remains relevant because it:

- Encourages structured experimentation over guesswork.

- Balances planning and action through small, fast feedback loops.

- Embeds learning into organizational culture.

- Promotes evidence-based decision-making over intuition.

Its simplicity allows application in both traditional industries and modern digital environments — from software testing to ESG performance improvement.

Real-World Examples of PDCA in Action

For ease of understanding, let us understand the PDCA cycle with real-world examples.

| Organization | Application Area | Results Achieved |

| Toyota | Manufacturing efficiency | Created the Toyota Production System, reducing waste and defects |

| Virginia Mason Medical Center (USA) | Healthcare quality | Cut medical errors by 74% through iterative PDCA cycles |

| Marriott International | Service operations | Improved customer satisfaction and reduced response time |

| Public Sector (Japan) | Urban planning | Streamlined public services and increased citizen satisfaction |

Across all cases, discipline and data were key success factors.

Common PDCA Mistakes (and How to Avoid Them)

| Common Mistake | Why It Happens | How to Prevent It |

| Skipping the “Check” step | Lack of time or data systems | Make data collection and review mandatory |

| Jumping into “Do” too early | Action bias, unclear goals | Spend adequate time defining problems |

| Ending at “Act” | Treating PDCA as a one-time effort | Reopen the cycle with new objectives |

| Poor documentation | Informal process ownership | Maintain logs of findings and best practices |

Advantages of the PDCA Cycle

- Ensures systematic, measurable improvement

- Encourages team collaboration and shared learning

- Reduces resource waste through testing before scaling

- Promotes accountability and transparency

- Enhances adaptability in dynamic environments

When PDCA May Need Adaptation

While PDCA is versatile, it may need modification when:

- Goals are abstract or creative (e.g., product design brainstorming)

- The project has long lead times (divide into sub-cycles)

- Systems are complex and interdependent (use parallel PDCA cycles)

In such cases, teams often integrate PDCA with Agile, Lean, or Six Sigma frameworks to maintain flexibility while preserving structure.

PDCA in Everyday Life

Individuals can also use PDCA for self-improvement:

- Plan: Set a fitness or study goal.

- Do: Implement your plan consistently.

- Check: Track progress using measurable metrics.

- Act: Refine your approach for better results.

For students, PDCA helps improve exam prep or project work through iterative learning.

Student Guidance Center: Our Counselors are Just a Click Away.

Conclusion

The Plan-Do-Check-Act (PDCA) Cycle remains a cornerstone of continuous improvement because it blends simplicity with scientific discipline. Whether applied to product quality, customer service, education, or personal growth, PDCA offers a repeatable, data-backed framework for achieving consistent progress.

By applying each step: Plan carefully, Do thoughtfully, Check objectively, and Act decisively, organizations and individuals can transform short-term changes into long-term success.

FAQs on PDCA Cycle

Q1. What is the purpose of the PDCA cycle?

Ans: To enable structured, data-driven improvement through planning, testing, evaluation, and action.

Q2. Can individuals use PDCA?

Ans: Yes. Students and professionals can use it to enhance productivity, learning, or habit formation.

Q3. How long should one PDCA cycle take?

Ans: It depends on project scope — from a few days for small tests to months for large organizational initiatives.

Q4. What tools can support PDCA implementation?

Ans: Use Fishbone Diagrams, Gantt Charts, Control Charts, or dashboard analytics tools.

Q5. Is PDCA still relevant today?

Ans: Absolutely. Its iterative, evidence-based nature aligns perfectly with modern Agile and Lean practices.

Tags

- #Business

Pearl Admission Enquiry

Subscribe to Pearl Blogs

By clicking the "Subscribe" button, I agree and accept the privacy policyyy of PEARL.